Inspection at plant:

-

Supervision/inspection during the course of rolling of finished steel products in the plant premises or at any nominated place within a radius from the plant and marking designated products for the export contract.

-

Supervision of drawing of samples at random or as specified in relevant specification of export contract for physical tests in case of semis and finished steel products (if not taken during rolling).

-

Scrutiny of works test certificate of each heat, in order to check and verify that the chemical analysis mentioned in the work’s test certificate is within specified range of the contractual specification.

-

Inspection of surface condition, dimensional and other physical specifications with tolerance check as per contractual specifications.

-

Issuing of certificate of quality as per the contractual specification.

-

In case of pig Iron, drawing random samples as per standard norms/as directed/as per stipulations from the stacks of Pig Storage Yard (PSY) of Steel Plant and determining the chemistry of Dust, Dirt & Moisture (DDM) as per contract before dispatching to port of area.

Pre-shipment inspection at plant site:

-

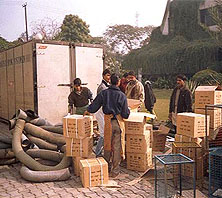

Supervision of loading of materials into the trailers/trucks/wagons at the plant site or at any designated place within a radius from the plant.

-

Counting the number of coils /bundles /pieces and submission of tally reports, size-wise, customer-wise for each movement along with relevant heat nos.

-

Supervision of marking /painting lot-wise as and when required.

-

Inspection of surface condition.

-

Inspection of storage of material in the plant.

-

Tally number of coils /bundles /pieces/at the time of dispatches to port or for diversions as specified, Export Stock Transfer –wise, (EST-wise), destination-wise and size-wise.

-

Identification and demarcation of rejected coils /bundles /pieces.

-

Determining and submission of dust, dirt and non-ferrous particles analysis for the quantities dispatched to Port Yard and submission of detailed sample analysis on calendar basis as applicable.

-

In case if the materials to be exported are to be selected from the available domestic stacks, the same has to be undertaken off-line inspection regarding the suitability of the domestic material for export as per the specifications of export order. Once, satisfied, the activities cited as above to be performed.

Pre-Shipment Inspection At Port (Relevant to Steel Products]:

-

Inspections of material while unloaded from the trailers/trucks/wagons at the port.

-

Supervision of size–wise stacking of material, which includes planning of the yard and allocating area for stacking of various materials for proper stacking so as to ease further handling.

-

Counting the number of coils /bundles/pieces and submission of tally reports EST wise/Lot-wise on day-to-day and consolidated on calendar basis [i.e. weekly, fortnightly, monthly, qrtly etc].

-

Supervision of marking /painting lot-wise/size-wise as and when required.

-

Inspection of surface condition.

-

Inspection of storage of material in stacks in the port.

-

Supervision of handling and re-stacking operation during stock verification.

Export from stacks:

-

Tally the number of coils /bundles /pieces at the time of dispatches for shipment, destination – wise, size-wise and Bill of Lading –wise on the basis of actual weight. Inspection of the cargo dispatched from yard and also on board tally. Reports giving the number of coils /bundles loaded in each hold /hatch on day-to-day basis.

-

Conduct preliminary and final draft survey to estimate the quantity in metric Tons of cargo in case of Pig Iron loaded on board the vessel after determining and deducting the weight of dust, dirt and non-ferrous particles as per the contractual terms and submission of detailed sample analysis on day to day basis during the course of loading and detailed report after completion of loading of the vessel.

-

Inspection of operations at the quay line at the time of shipment.

-

Identification and demarcation of rejected coils /bundles /pieces.

-

Inspection of the vessel’s hold/hatches before commencement of loading for suitability.

-

Stowage of cargo, checking of lashing and Dunn aging to cargo etc.

-

To examine and confirm that the vessel is in conformity with the details given by the buyer in their communication and accepted by consignor/shipper.

-

Inspection of the gears of the vessel and confirm the same are as per the details given by the owners of the vessel/buyers. If the lifting capacity of cranes of the vessel is not in accordance with the details given by the buyers, a survey should be conducted so as to determine the actual lifting capacity of the cranes and based on these, the loading rate has to be determined.

Domestic diversion from the stacks:

-

Supervision of loading of such materials into trucks for diversion to domestic stockyards/Plant/customers.

-

Identification and supervision of demarcation and stacking of materials to be diverted.

-

Analysis and testing of pig Iron chips and dust arising in shipments/wharf returns, diversions and / or in stock verifications etc., detailed analysis giving the DDM to be submitted lot wise immediately on completion of each activity/diversion /shipment.

-

Report of materials loaded with Delivery Challans (DCs)/ Stock Transfer Challans (STCs) reference in case of diversion of material from port to domestic customer’s /stockyards/plant.

-

A weekly report of stack-wise stock at port is to be handed over to consignee/consignor office.

-

A monthly inspection of stored material at port regarding the condition of the stock is to be furnished. In addition to the above, we can also undertake quantification of iron/stock in the form of heaps/mounts at mines end by sextants methods.

|

|